(Blåtryck, indigo och blåerier)

The project is supported by The National Swedish Handicraft Council (Nämnden för Hemslöjdsfrågor)

Before my visit

About the dye houses and the cultural heritage that they carry:

There are around five active dye houses operating currently in Hungary (2023), where blue/indigo dyeing is a tradition. I will be visiting as many as I can and the Museum of Blue Dyeing this summer. The idea is to create a smaller set up of a dye house and bring the craft back to Sweden. I’ve been growing woad and japanese indigo ( indigo blue pigment bearing plants) since 2016 and local sustainable production is very important to me. Indigo resist dyeing became part of the UNESCO cultural heritage in 2018, but it’s still a craft that’s slowly disappearing. As hand-made traditional methods had been replaced with machines, their fast production endangered them along time ago. I feel it’s important to preserve and to be able to spread the knowledge and through that safeguard it for future generations.

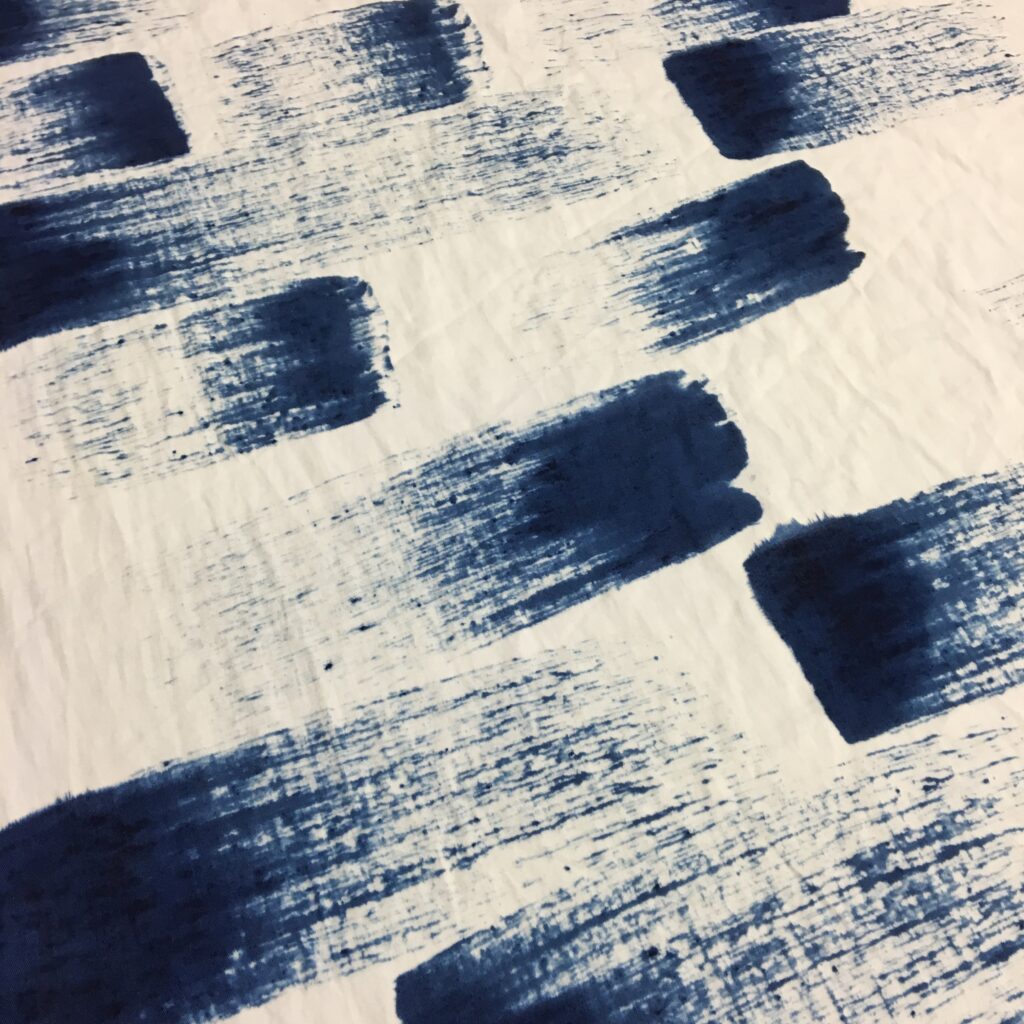

As part of the preparation for the technical side of the project I’ve been experimenting with various indigo applications on textiles. (2023 febuary-march)

“Reversed” blue-printing

Traditionally blue printing intails application of a resist paste onto the fabric then dyeing in an indigo vat. Here I´m replicating the mechanism of a vat during printing/painting and thus creating an opposite effect than blue resist dyeing.

Here you can see the development of a pattern, the indigo oxidizing and the blue colour is developing.

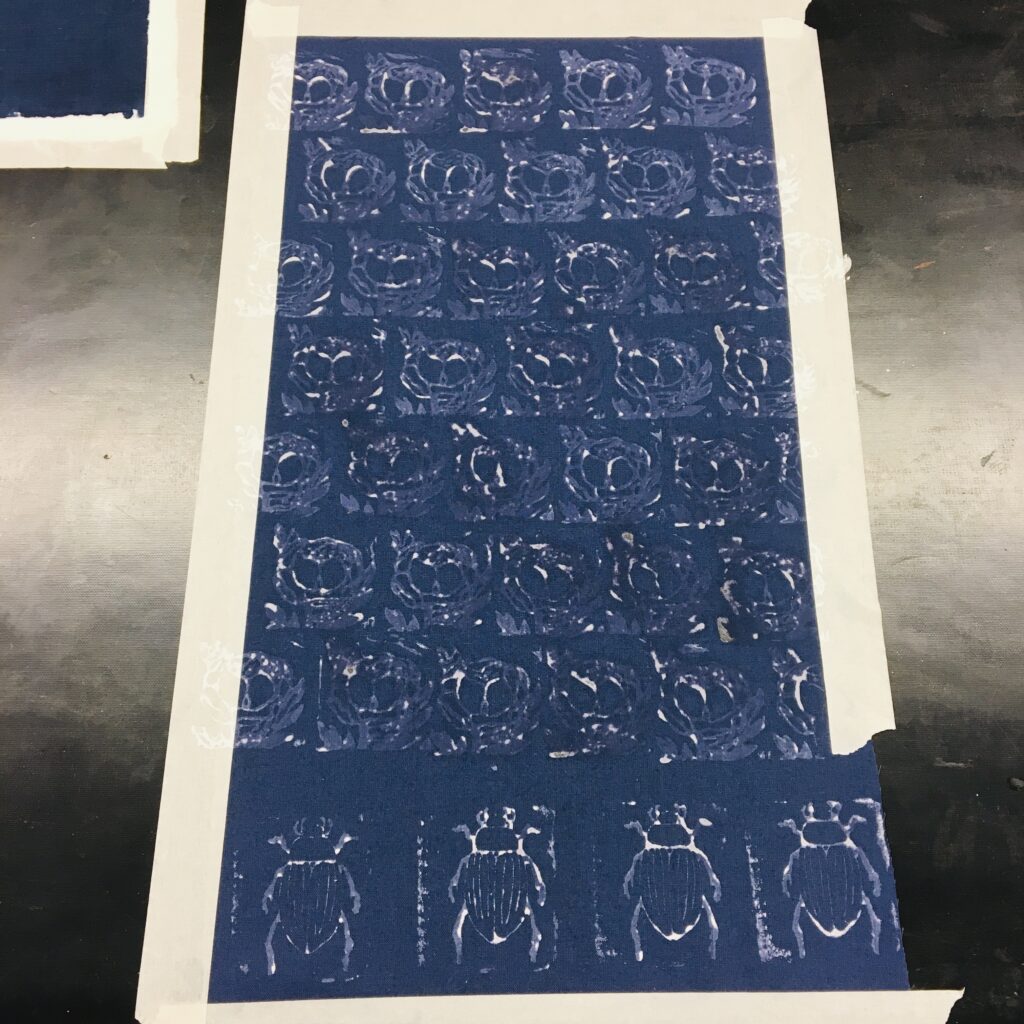

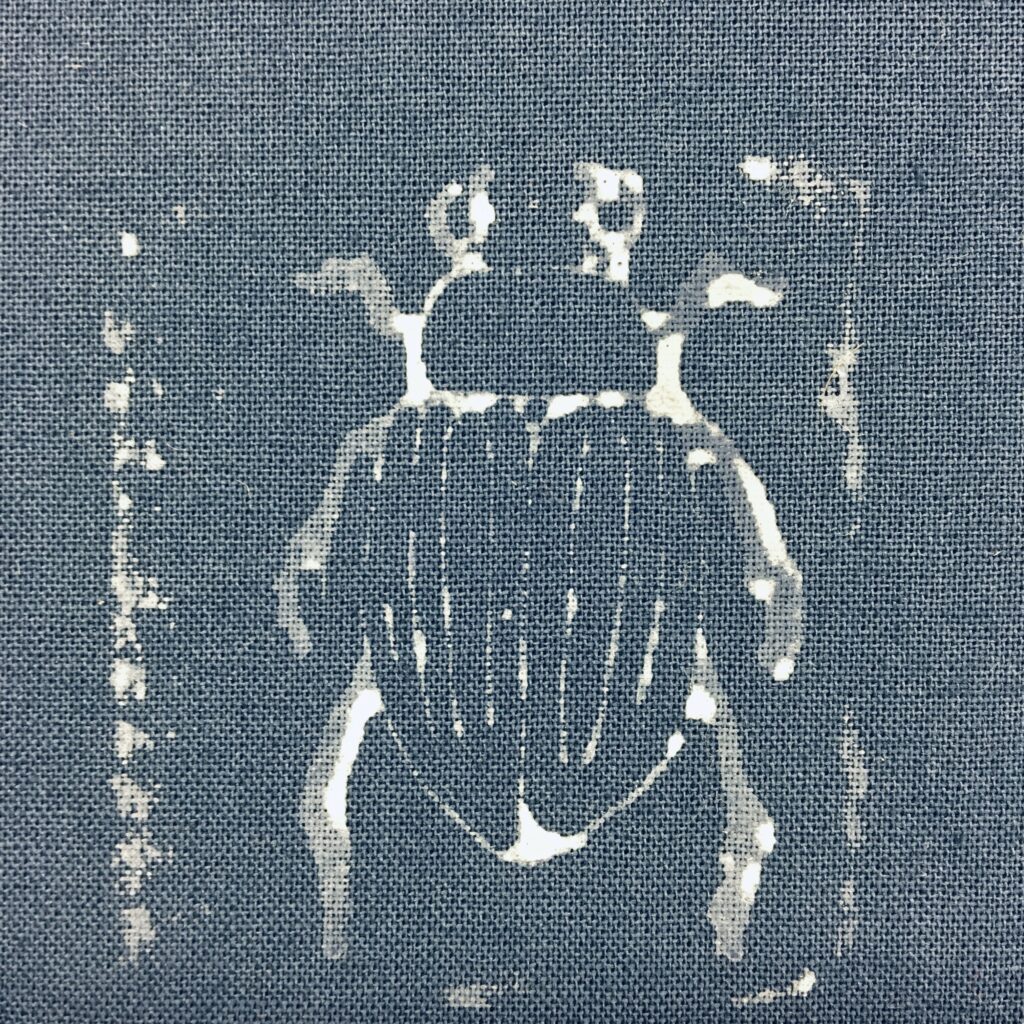

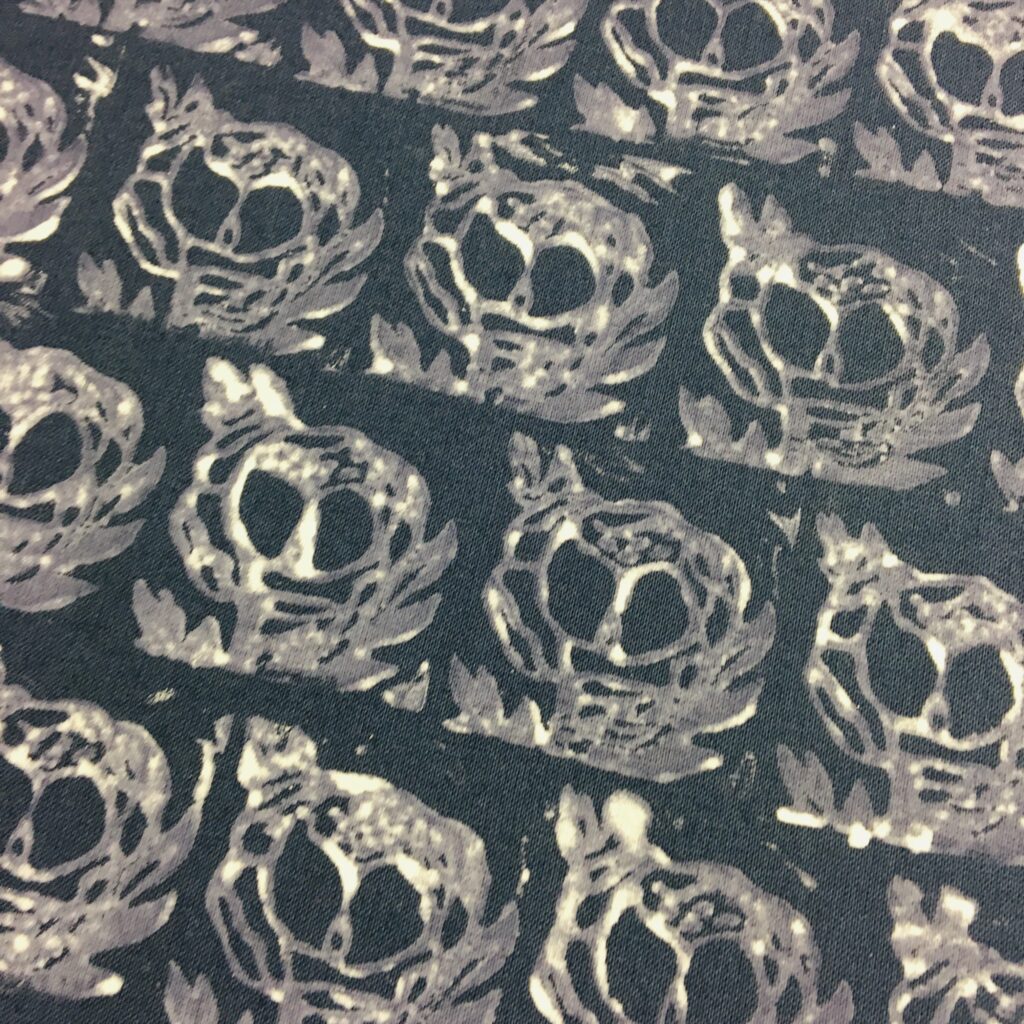

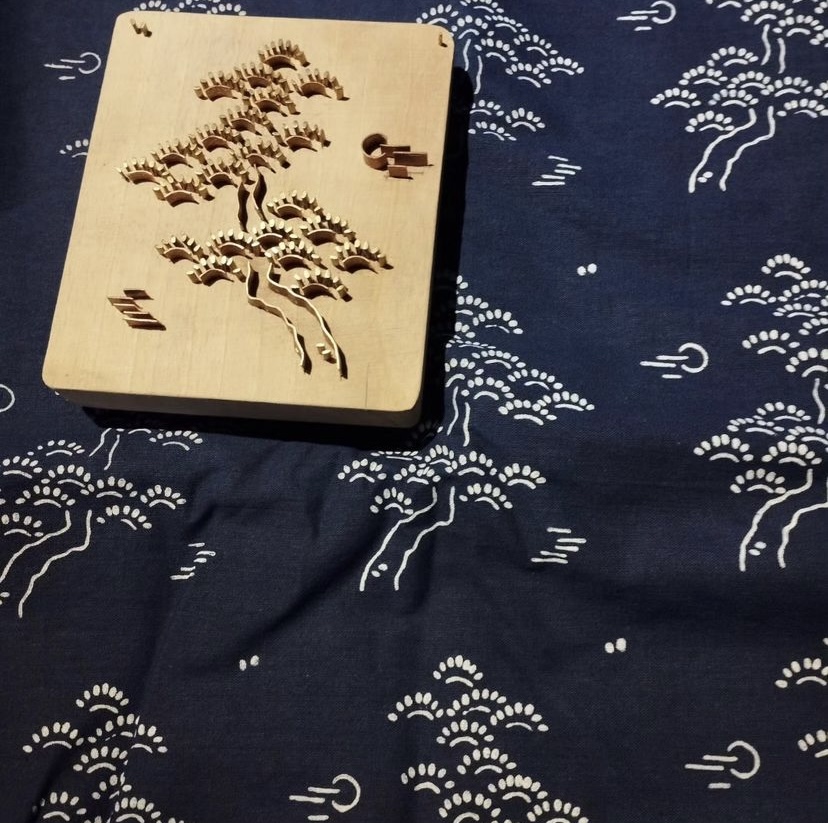

Discharge printing. This has a closer effect to the blue printing, but here the fabric is dyed first and then the colour is removed with chemicals. This is synthetic dyed fabric straight from the shop and printed with printing blocks I made.

My study trip to the Hungarian dye houses – summer 2023

Here you can read about the places I visited. It’s a summary of the events and the final result of the trip. Hope you’ll enjoy it!

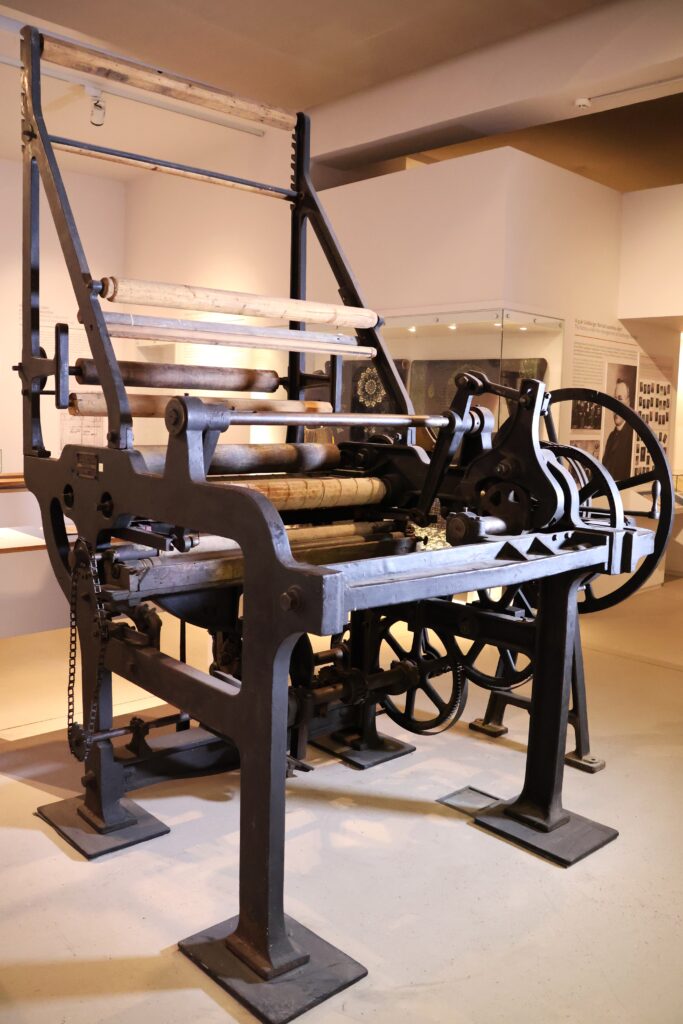

Goldberger Textile Museum in Budapest

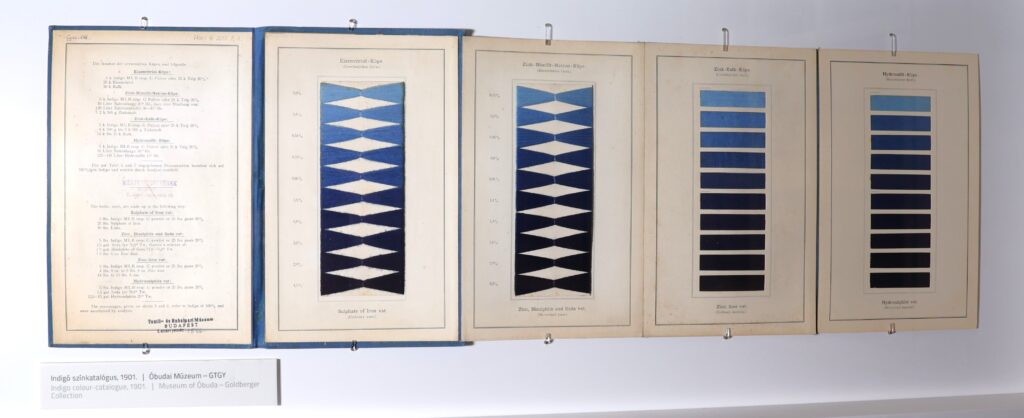

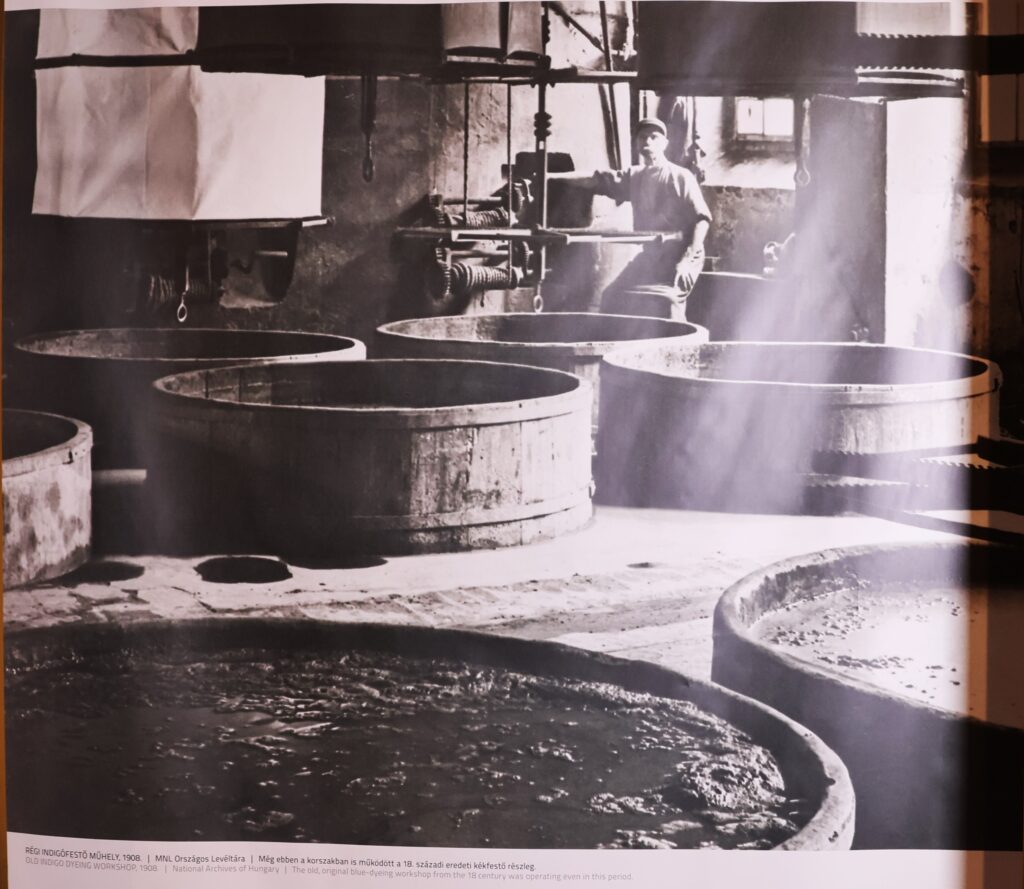

The Goldberger textile shop was opened in 1779 and an indigo dye house was established on the premises in 1784. Unfortunately there’s almost nothing that is left from this time. Most of the items are loaned from other dye houses. They industrialised as economy went well, but the indigo dye house was used for a long time.

The dye house in Győr

The dye house was established in 1906 and today it’s the fourth generation who carries on with the tradition.

A day’s work shown in less than a minute. Preparing the fabrics before printing:

Tools for making a printing block:

Testing and creating my printing block. This was a long process throughout 2-3 days:

Printing with the “pap” (resist paste):

Dyeing in the indigo vat. Here you can see roughly the steps it involves, but of course there´s a lot more to it:

Heading to Pápa. A real retro-train ride through the hungarian counryside:

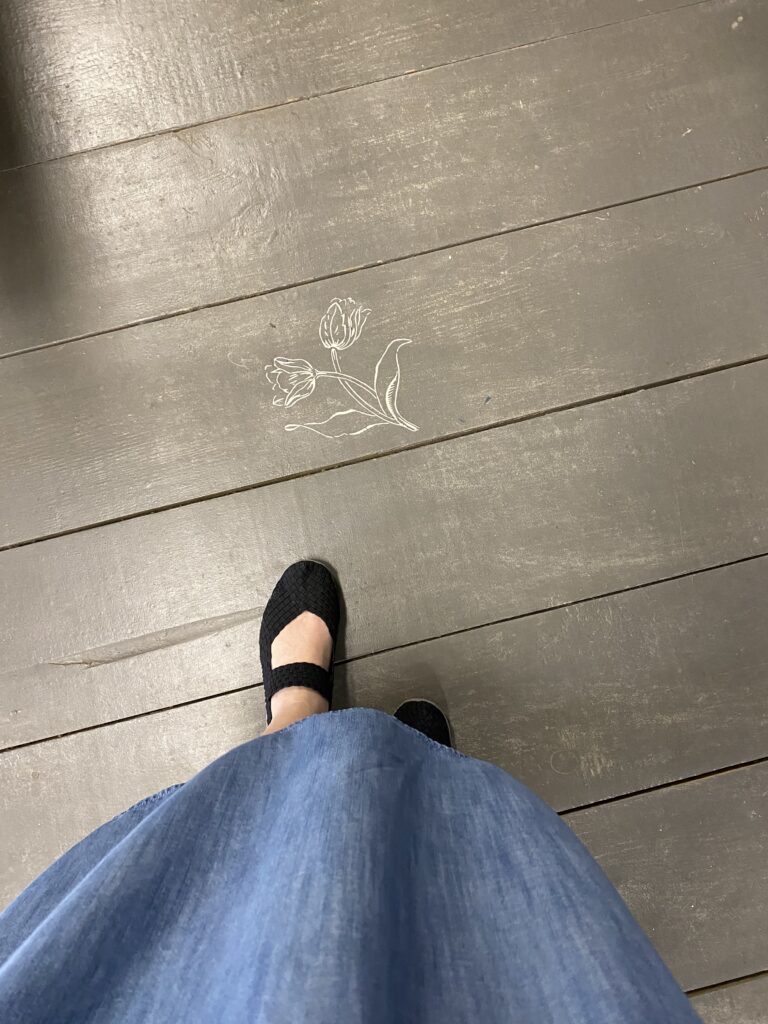

Blue-printing Dye House Museum in Pápa

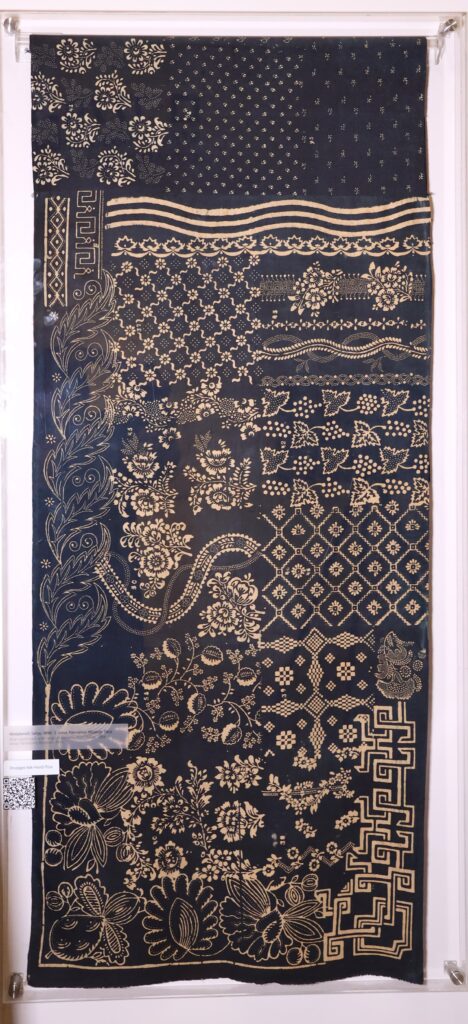

A quick tour of the museum introducing the various rooms used during the process:

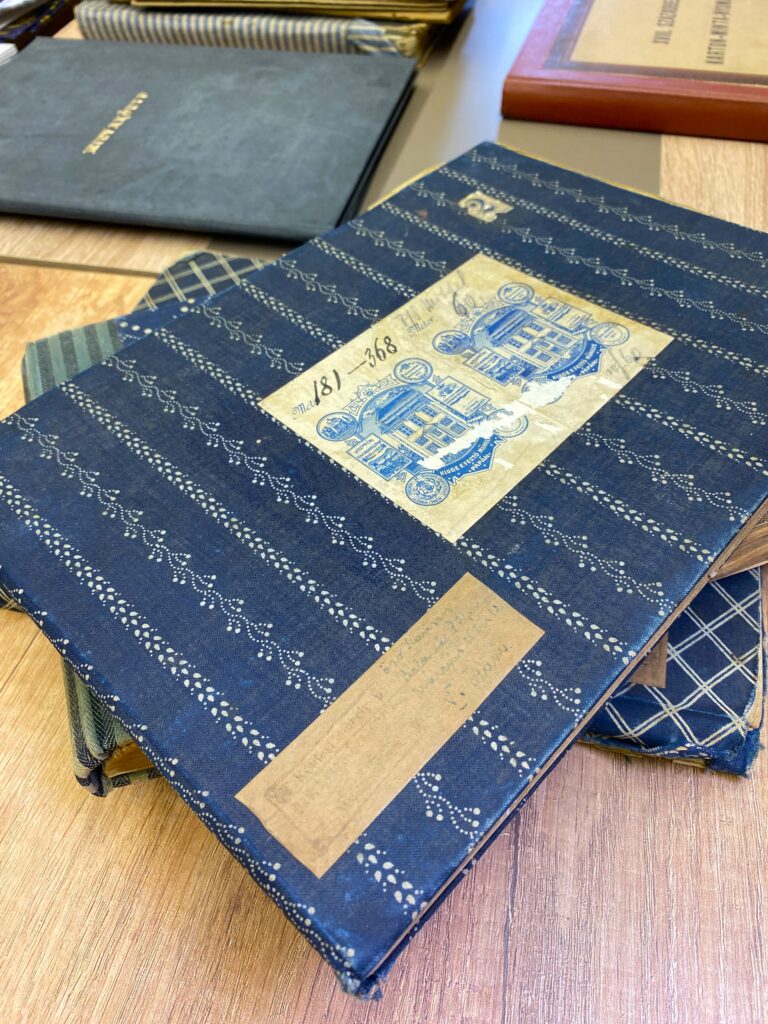

The archives

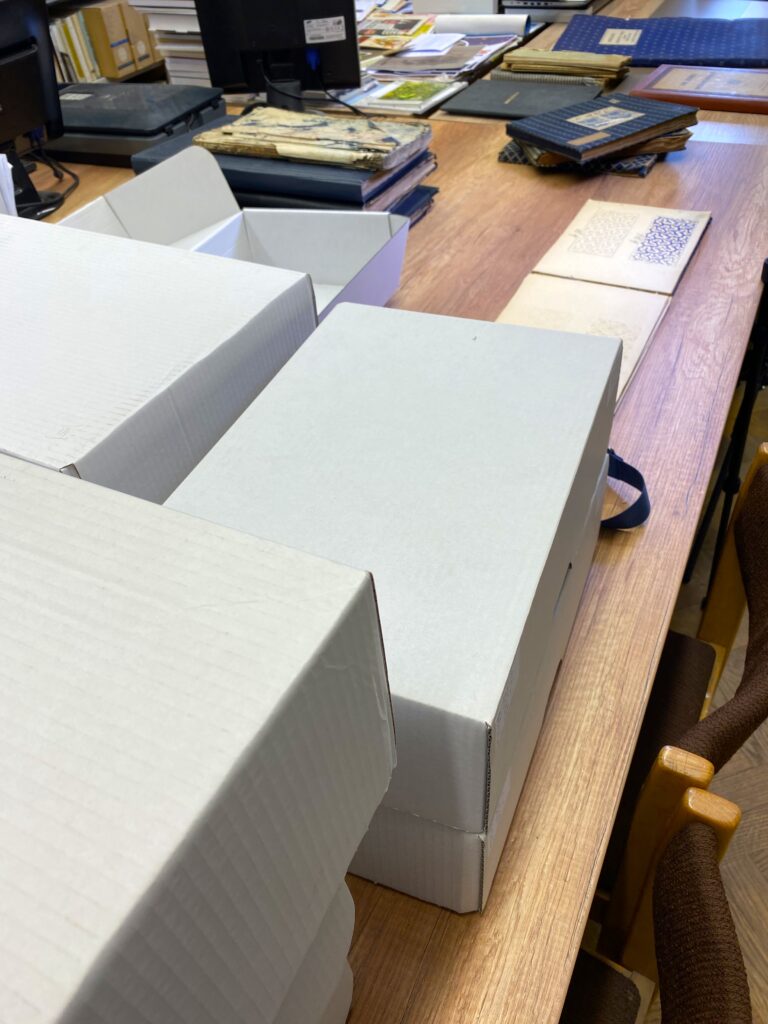

The archive at the museum has a vast collection of sample books and pattern books:

One of the many sample books:

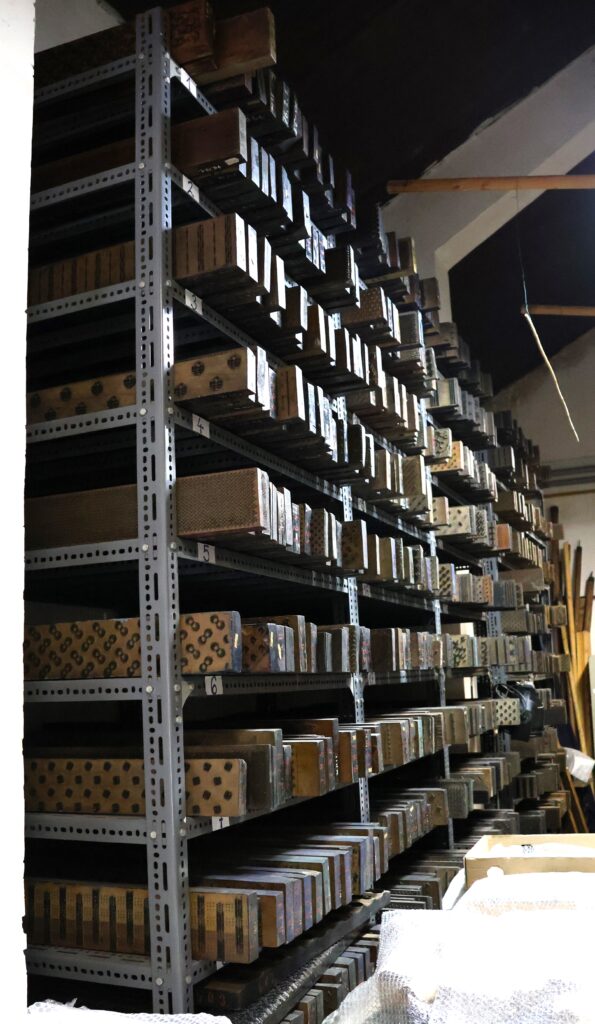

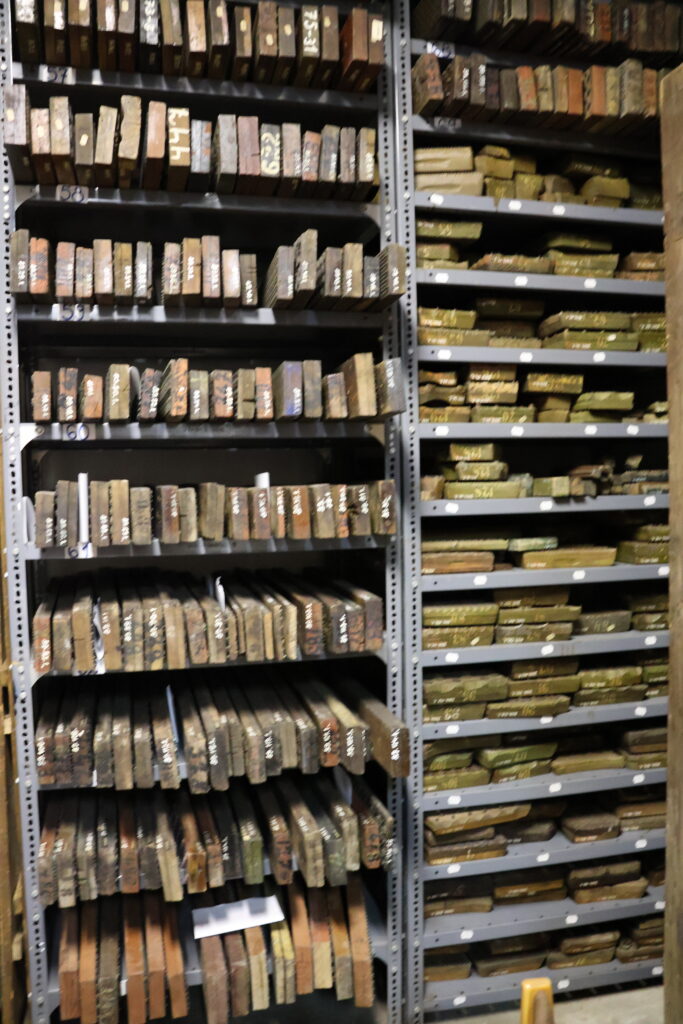

Roughly a thousand printing blocks are in the museum’s collection, both for hand- and machine printing:

The dye house in Bácsalmás

The dye house has been established in 1879 and the Skorutyák family owns it. It goes back five generations, but today a close family friend, Zoltán Bakos is the one who operates the workshop.

A specialty of the dye house is printing to rhythm. Param-pam-pam:

Here you can see the Perrotine machine at Bácsalmás in operation:

After this fantastic trip I held a presentation at From/Design Center in Malmö in October 2023 where I was really happy to see the big interest for this unique technique.

I’m hoping to have the opportunity to continue further my research and share my findings.

Thank you to The National Swedish Handycraft Council for the support!